Why Older Honda Engines Keep Outlasting Modern Ones: A Deep Dive Into Honda’s R18 Reliability and i‑VTEC Engineering

Modern engines are more advanced than ever. Turbocharging, direct injection, hybrid systems, and complex emissions technology have transformed performance and efficiency across the automotive world. But with that progress comes a familiar debate: are modern engines actually less reliable than older naturally aspirated engines?

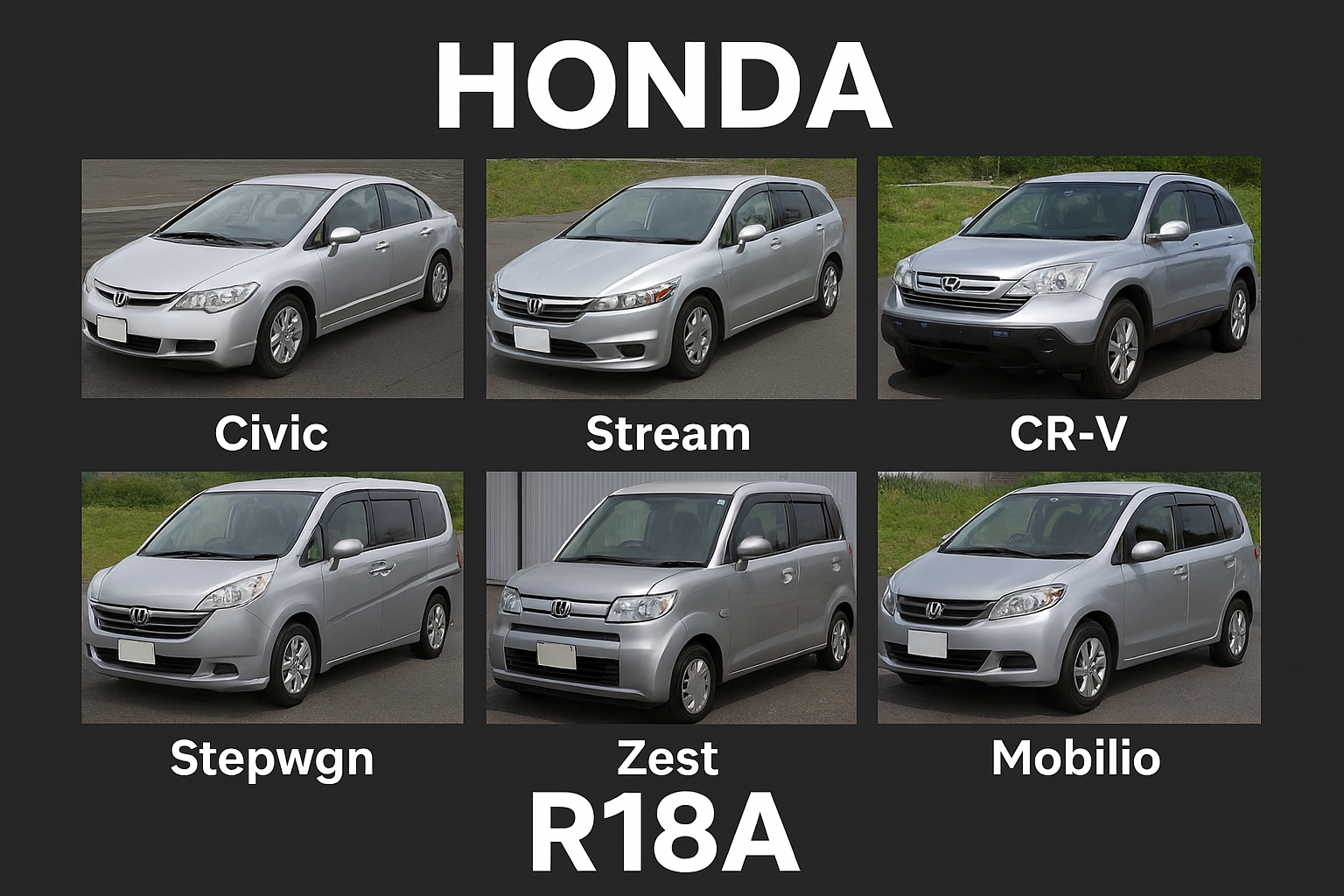

A recent teardown of Honda’s R18 engine — the 1.8‑litre NA motor found in 8th‑ and 9th‑generation Honda Civics — gives us a perfect case study. With over 210,000 km on the clock, the engine still showed impressive durability. And when you combine that with the engineering philosophy behind Honda’s SOHC i‑VTEC system, you start to see why this engine has earned such a reputation for long‑term reliability.

This article blends real‑world teardown results with a technical look at how the R18A works — and why proper maintenance matters more than ever for Honda owners, JDM enthusiasts, and anyone comparing modern turbo engines vs older NA engines.

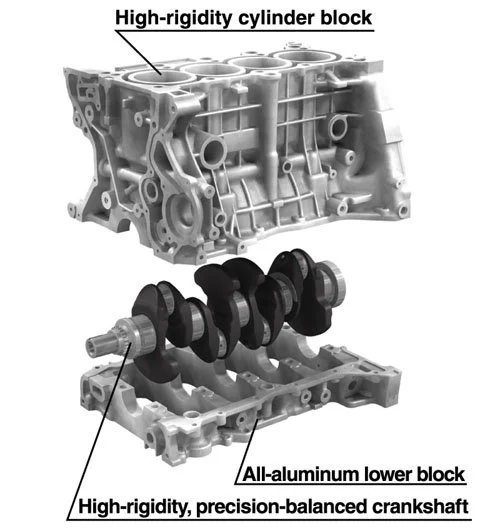

Inside the Honda R18: Simple Engineering That Just Works

The Honda R18 is a reminder of how effective simple, well‑thought‑out engineering can be. Key features include:

Port fuel injection (keeps intake valves cleaner)

Economy‑focused SOHC i‑VTEC system

Naturally aspirated design (less heat, fewer failure points)

Lightweight components like a plastic intake manifold

Low internal friction thanks to modern materials and coatings

During the teardown, the only major issue was a blown head gasket between cylinders two and three — caused by prolonged overheating, not a design flaw. Once coolant levels drop, temperature regulation fails, and gasket failure becomes inevitable.

The bottom end — crankshaft, rods, oil pan — showed normal wear for an engine with over 130,000 miles, proving how robust the R18 platform really is.

This is exactly why the R18 is often praised in Honda reliability discussions, Civic buyer guides, and JDM engine comparison articles.

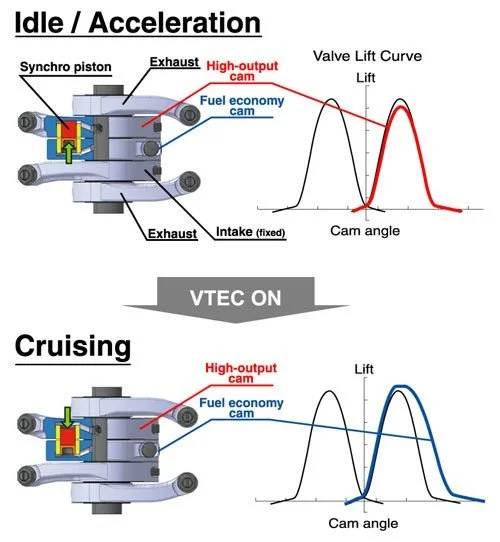

How Honda’s R18A i‑VTEC System Actually Works

To understand why the R18A is so efficient and reliable, you need to look at its unique SOHC i‑VTEC system — a completely different approach from the high‑rpm VTEC systems Honda fans grew up with.

Honda designed the R18A around two real‑world driving modes:

1. Normal driving & performance mode

This uses the “hot” cam lobes — the more aggressive profiles — giving the R18A surprisingly strong low‑end torque and acceleration for a 1.8 NA engine.

2. Economy mode

This is where the R18A becomes clever.

Under light throttle and steady cruising, the engine switches to a fuel‑saving cam profile. Instead of restricting airflow with a nearly closed throttle plate (which causes pumping losses), Honda delays the intake valve closing so excess air is pushed back into the intake manifold.

This means:

The throttle stays almost fully open

The engine breathes freely

Pumping losses drop by up to 16%

Fuel economy improves dramatically

This system only works because of Drive‑By‑Wire (DBW), which allows the ECU to control the throttle plate independently of your foot.

The result is a dual‑mode engine that behaves like a torquey 2.0‑litre around town, but sips fuel like a 1.5‑litre on the motorway — a major selling point for daily drivers, commuters, and fuel‑efficient JDM imports.

Why the R18A’s Simplicity Helps Reliability

The R18A avoids many of the long‑term issues seen in modern turbo engines:

No turbo = less heat and pressure

Port injection = cleaner valves

Mild cam profiles = less wear

Fewer sensors and high‑pressure systems

Lower stress on internal components

It’s not a performance engine — but it’s built to last. This is why the R18 is often recommended in reliable Honda engine lists, first‑car guides, and budget‑friendly JDM import recommendations .

Are Modern Engines Really Less Reliable? A Balanced View

There’s a growing belief that modern turbocharged engines don’t last as long as older NA motors. But the reality is more nuanced.

We don’t fully agree that modern engines are “poor.”

What we do see is that modern engines are less forgiving when maintenance is skipped.

Why modern engines struggle when neglected:

Turbochargers generate more heat and stress

Direct injection can cause carbon buildup

High‑pressure fuel systems are more sensitive

Long manufacturer service intervals accelerate wear

Cheap oil and poor‑quality fuel reduce engine life

Fuel quality matters — E5 vs E10

Using E5 petrol can help reduce carbon buildup and keep injectors cleaner, especially in direct‑injection engines.

Service intervals matter even more

We’ve consistently seen better long‑term results from owners who service their engines every 7,000 miles, not the extended 12k–20k intervals manufacturers advertise.

Fresh oil, quality filters, and proper coolant levels are the real foundation of engine longevity — regardless of age or technology.

Pros & Cons: Older NA Engines vs Modern Turbo Engines

Pros of Older Naturally Aspirated Engines (like Honda’s R18)

Simple design with fewer failure points

Port injection reduces carbon buildup

Mild cam profiles reduce wear

Easier to diagnose and repair

Proven long‑term durability

Less heat and stress without forced induction

Cons of Older NA Engines

Lower performance

Less efficient

Outdated technology

Limited tuning potential

Not as responsive as modern turbo engines

Pros of Modern Turbocharged Engines

Higher efficiency

More power from smaller displacement

Lower emissions

Better drivability and torque

Hybrid options for even more efficiency

Cons of Modern Turbo Engines

More complexity = more potential issues

Direct injection carbon buildup

Turbo systems run hotter

Sensitive to poor maintenance

Fuel quality matters more

Conclusion: Reliability Comes Down to Maintenance, Not Just Design

The Honda R18 teardown — combined with the engineering behind its SOHC i‑VTEC system — shows exactly why older engines like this can run huge mileage with minimal drama. Simple engineering, fewer moving parts, and designs that don’t punish you for missing a service by a few hundred miles.

But it also highlights a bigger truth: modern engines aren’t inherently unreliable — they’re just less tolerant of neglect.

Use good fuel (E5), stick to 7,000‑mile service intervals, and keep an eye on coolant and oil levels, and even today’s turbocharged engines can deliver long, trouble‑free life.

Every engine has strengths and weaknesses. The real difference comes from how it’s maintained.

What’s your take — are modern engines too complex, or is proper maintenance the real key to long‑term reliability?

How This Blog Helps You Choose the Right JDM Car

If you’re reading this, you’re already the kind of buyer who cares about engine reliability, maintenance history, and long‑term ownership costs — and that’s exactly where Touge Imports specialises.

How we help buyers:

We source clean, reliable JDM cars with verified history (CarVX & Physical inspections)

We prioritise engines known for long‑term durability (like the R18, K‑series, 1NZ, 2ZR, EJ20 NA, etc.)

We provide transparent inspections and honest condition reports

We help you choose the right engine for your needs — NA, turbo, hybrid, or diesel

We handle the entire import process from Japan to your driveway

Why this matters

A blog like this doesn’t just explain engine reliability — it helps you understand what to look for when buying a used or imported car. And when you’re ready, we can help you find a car that fits:

Your budget

Your driving style

Your reliability expectations

Your long‑term plans

Want help choosing your next JDM import?

Reach out — we’ll guide you through the process and help you find something clean, reliable, and worth owning.

Want to see the video version of this?

Come find us at: